If you’re unsure whether your file type is suitable for use, please contact us for confirmation. We accept a range of files types including. If you have a design file you would like us to use, you’re welcome to send it to us. G-code includes instructions for linear moves, tool type, spindle speed and feed rate.

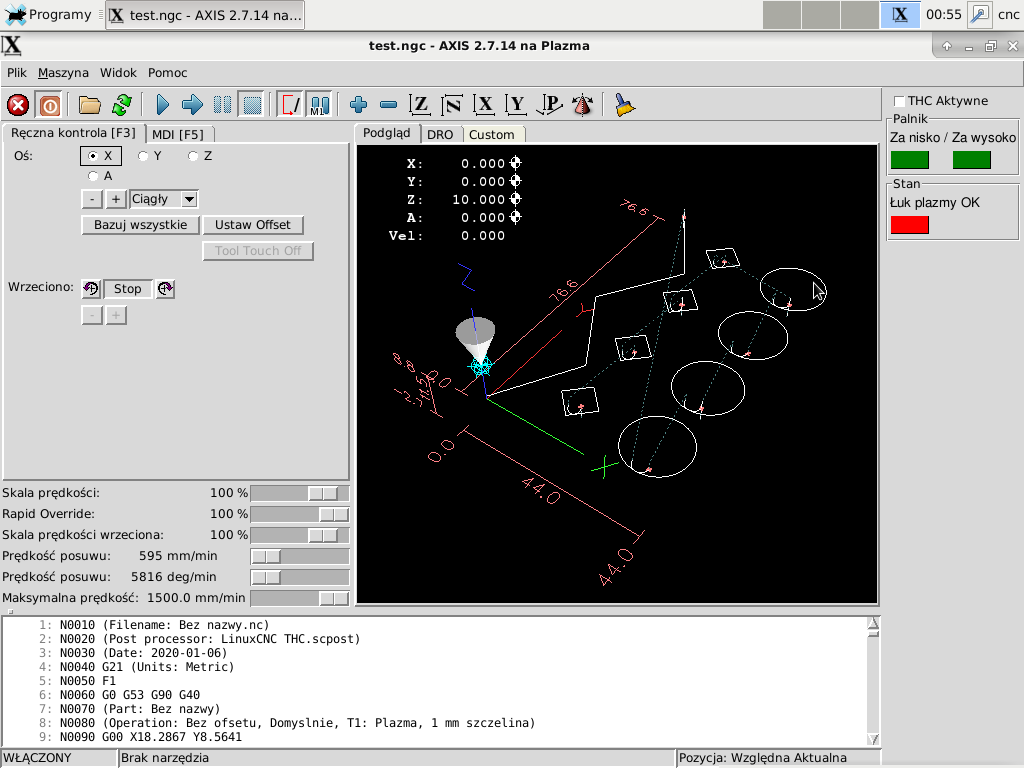

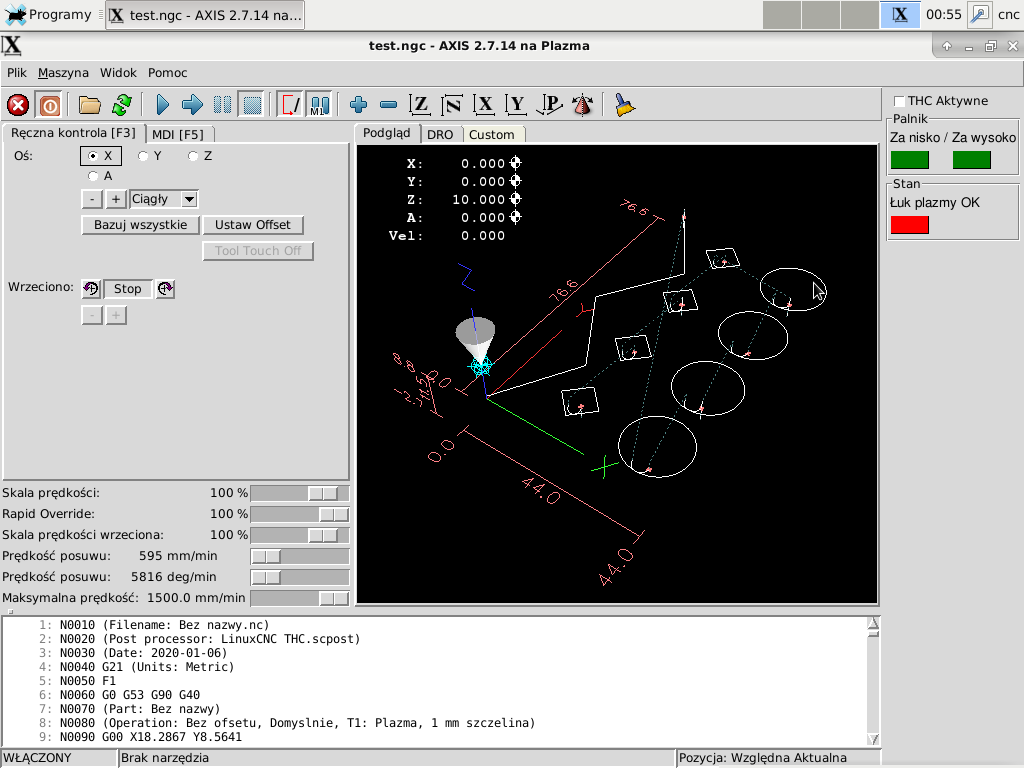

Finally, it sets certain parameters such as speed, the pierce height and voltage.Īfter the model has been properly prepared, the file information must be converted to a language that the CNC machines can understand (G-code). It designates a set of coordinates (known as a toolpath) that the CNC machine can follow. #Cambam plasma software#

CAM software checks the model for any errors in geometry. Some other software such as Fusion 360 has both CAD and CAM functionality.ĬAM takes several steps to help ensure that CNC machines can properly read file instructions and create a final product. These are some examples of purely CAM software: These numerical instructions are referred to as G-code. When a design has been finalised in CAD it can be imported to CAM software.Ĭomputer-Aided Manufacturing (CAM) software are specialist programs used to create detailed numerical instructions that CNC machinery can interpret. These contain physical properties that can be utilised by CAM software. In CAD, the designer will create a model of the intended object. Some examples of CAD software include:Įngineering processes begin life in CAD software. What is CAD Software?Ĭomputer-Aided Design (CAD) software are programs used to create, modify, analyse or optimise any given design. Whilst designs are generally formulated in CAD software, they cannot be fully created until a CAD file is imported into CAM software.Īlthough similar in name, these two types of software offer very distinct benefits. Understanding CNC FilesĬNC machinery requires specific files to properly operate. This type of CNC machine is suitable for cutting sturdier materials such as titanium and steel. However, milling machines have more torque. Routers cut much faster than milling machines do. CNC Milling MachinesĬNC milling machines are very similar in concept to CNC routers. Here, the laser beam melts away unwanted parts of the material, whilst a high-pressure gas (such as compressed air, nitrogen or oxygen) removes it. The most common form of laser cutting is referred to as “vaporisation cutting”. Similar in function to plasma cutters, laser cutters are also used for machining sheet metals (they can also be used to cut polyethylene foam). They’re suitable for machining metals such as steel, brass, aluminium and copper. Plasma cutters utilise intense heat to melt away unwanted areas of a material. It is then clamped to the router’s table the drill bit is moved directly above the centre and the operator runs the G-code function.ĭon’t know what G-code is? Not to worry, we’ll discuss this as well as CNC files shortly.

To create a product, the centre of the material is determined by a human operator. They’re used to cut a variety of materials including foam.

This is the most versatile and common type of CNC machine. Here are some examples of various CNC machines.

The type required entirely depends on the material being machined and the product being created. There are a variety of different types of CNC machines. Some other materials that can be cut with a CNC machine include composites, wood, steel, brass, aluminium, carbon fibre, plastics and glass. Whilst we at GB Foam use CNC machinery solely for creating custom foam products, there are plenty of materials that can be worked with CNC machines. A CNC foam cutter is a machine capable of cutting foam assisted by a computer system. Call on 01494 441177 or email What is CNC Machining?ĬNC stands for Computer Numerical Control. If you’re in need of a custom foam product, we can create it for you! Speak to one of our experts today to discuss your requirements. We can even replicate your design as many times as you require. Our CNC foam cutting services help to guarantee the highest level of precision. Over the years, we’ve worked with a multitude of top-name brands, creating unique foam products to precise specifications. Our CNC foam cutting services are just one of the many ways in which we’re working to deliver the perfect products to our customers. As the UK’s leading foam converter, we’re always searching for new and innovative means to create the foam products you need.

0 kommentar(er)

0 kommentar(er)